Proofing

We supply innovative bakery equipment. Whatever your requirements, Bakery Combinations offers a wide range of end-to-end industrial solutions. From raw ingredients to the finished product, we have the technical knowledge, experience, and network to provide the perfect bespoke solution for your business.

The proofing process is one of the most delicate due to heat treatments. In order to obtain a high- quality product, it’s important to perfectly calibrate your industrial equipment so as to ensure you do not alter food properties.Throughout this phase it is essential to keep temperature and humidity constant to ensure optimum dough leavening, while maintaining the product’s organoleptic properties.

This is why industrial proofing is carried out inside an insulated cabinet that allows the accurate control of these parameters, consequently maximising the production cycle specific to each product. Throughout this process, the temperature and humidity settings can be changed based on the product.

By doing so, the products quality and end result can vary depending on your needs. If you wish to change the level, specific to seasonal environmental conditions, you can do so by favouring the natural leavening of both loose products and those in pans and containers.

Proofing by Tecnopool

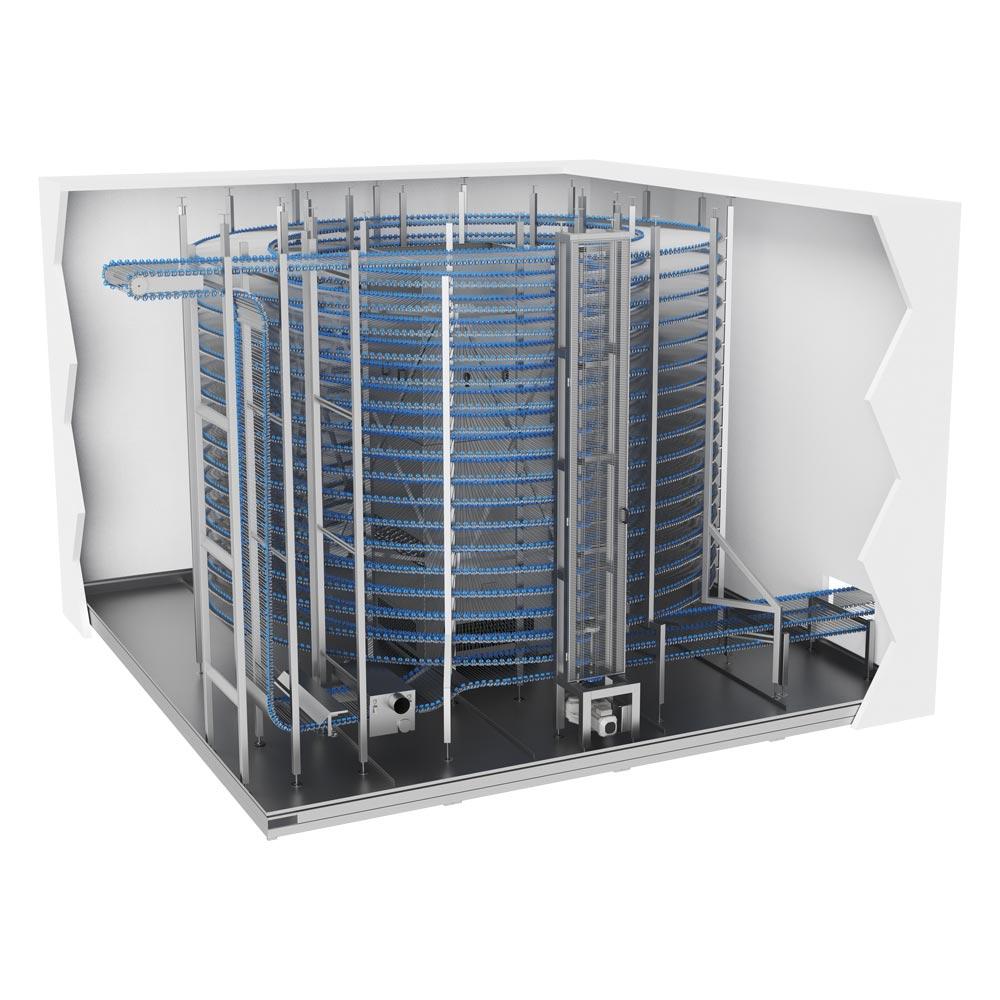

Tecnopool’s spiral proofing system enhances the natural leavening of bakery products prior to baking. The process takes place in an insulated stainless-steel Cabinet that allows to closely monitor the temperature and humidity. The quality and accuracy of the proofing treatment prevent the product from sticking to the resting surface, whether on the T-Worth conveyor belt, in pans or trays or on special supports. Therefore, the product will not suffer any mechanical changes of shape.

Thanks to its distinctive spiral configuration, the proofing system allows to make the most of the available space in height, thus reducing the machine’s footprint to a minimum and making it adaptable to the most constrained processing spaces. The T-Worth conveyor belt is entirely made of stainless steel, while the special drum-free construction system makes every part of the spiral easily reachable, enabling both easy maintenance and compliance with the strictest health and hygiene standards requested by the food industry.

Proofing by Mecatherm

Mecatherm offers different proofing solutions, depending on the type of product, required capacity and size/type of carrier required.

M-UB

The M-UB handling system offers flexibility, adapting to diverse products and future needs while ensuring smooth, consistent handling at all stages. It is designed for ease of use, simplifying daily operations and reducing costs, all while maintaining reliable product quality.

MVS

Similarly, the MVS proofer system is highly adaptable to various processing capacities and types, featuring a simple FIFO operation for efficiency. With over 1,000 global installations, it guarantees consistent performance, making both systems ideal for boosting productivity and quality in industrial settings.

EMP 2

The EMP 2 proofer offers flexibility with its modular design, allowing for adjustments in capacity and process time by adding or bypassing elevators. With an operating pace of up to 400 trays per hour, it delivers reliable performance while ensuring a consistent, regulated atmosphere for fermentation.

TFP

The TFP proofer, provides modularity with the ability to adjust capacity based on the number of elevators used, offering an operating speed of up to 450 trays per hour. Both systems deliver excellent performance, guaranteeing reliability and efficiency in proofing processes.

We supply innovative bakery equipment